Structuring the Bill Of Material

Well-made products are documented with a BOM. This list of articles, parts, assemblies and subunits that represent the product design (EBOM), or how the product is manufactured (MBOM), serves as a way to maintain an accurate list of required components.

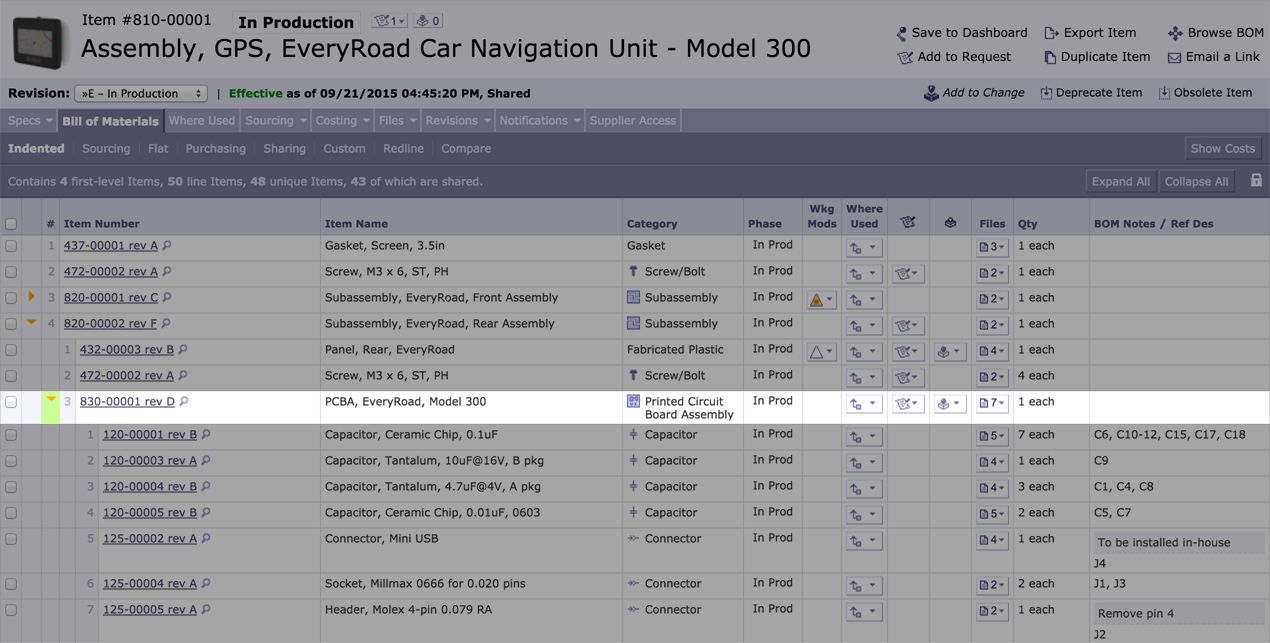

A bill of materials at multiple levels, also known as an indented (bill of materials), displays parent-child relationships and shows the hierarchical structure of assemblies and their parts and components.

A bill of materials with multiple levels is essentially a nested list whose parts or items are listed in two or more levels of detail to illustrate multiple assemblies within the bill of material of a product. A BOM at one level, on the other hand, displays one level in an assembly and only the components needed to create that assembly are displayed.

Multi-level BOM Example

Choose which BOM structure to use

To define the bill of materials structure that best fits your needs, it is important to consider who will use the bill of materials, as well as the type of product you are building with the bill of materials. Ask yourself the following questions. Is your bill of material used internally for technical purposes? Is your bill of materials shared with a contract manufacturer, partner or other employee? What types of products do you make? What is the complexity and configurability of your products? These are just a few of the important factors that you need to consider when structuring your bill of materials. We cover each of these below in more detail.

For internal technical use, the BOM structure can vary based on the technical discipline. Designers and mechanical engineers often prefer a bill of materials with nested subunits because the subunits can be used for different product designs. In these cases, the BOM often displays customized components and provides essential information about the structure of the product. Electrical engineers, on the other hand, prefer bill of materials that are not nested, because they usually record ready-made components. Here the way in which the components are connected to each other (the diagram) is important for the electrical engineer, but not for the overall structure of the bill of materials.

When sharing parts lists with a contract manufacturer, partner or employee, it can be useful to use a parts list with some structure. Nesting and creating parts in your bill of material allows you to isolate specific parts (sub-assemblies), so that you can only share the design data that you need for your partner or CM (Contract Manufacturer). If your partner helps you with a design, you can choose to share only the sub-assembly related to their work, protecting the intellectual property associated with the other sub-assemblies of the product design.

A bill of materials on multiple levels is also useful if you have complex and highly configurable products. Updating a sub-composition within a larger product composition can be done quickly if you have structured your bill of materials as a multi-level, because a change order only affects a subset of the product. The sub-composition can be revised and, if necessary, used in several assemblies at a higher level. The assemblies at a higher level only need to be revised in the structure of the product structure if the shape and function rules so require.

A bill of materials at multiple levels can also reduce the risk if you have products with parts with long lead times, high inventory costs or suppliers from one source. A bill of materials with sub-units allows you to locate potential alternatives to expensive components and provides a better understanding of assemblies and sub-units that may require additional work. Ultimately, this structure can help address issues that may arise before or during the production process.

By taking into account the stakeholders who use the BOM and the types of products you build, you can better determine the BOM structure that is appropriate for your organization.

The problems with managing BOMs at multiple levels in Excel

Excel BOM spreadsheets are a commonly used tool for small and medium-sized manufacturers who are just starting to manage product data. Although Excel offers some first benefits – it’s actually free (because you already have it) and easily accessible – managing multiple-level bills of materials in Excel can be extremely annoying and time-consuming.

Because every cell in an Excel BOM requires a manual operation (data entry, copying and pasting, making formulas, etc.), it is easy to make a mistake, which means that continuous manual checking is required to ensure that input and changes are correct. This is manageable when your bill of material is just a few items, but when you work with indented parts lists that contain hundreds or thousands of parts, the manual assessment of each cell is not scalable. And although Excel is good at analyzing numerical data, compiling BOM quantity and cost information in a spreadsheet can be too complicated in the case of deeply nested parent – child relationships.

If you plan to use Excel to manage bill of materials on multiple levels, there are a few questions that you may want to answer first. Can you limit the risks of manual data entry? Will the inability to quickly collect cost data become a problem for your organization?

How Arena PLM helps manage BOMs on multiple levels

Arena PLM, with Bill of Material and Change Management, offers a more efficient approach to managing BOMs with multiple levels than Excel. Because the software is built on a relational database, you can create an unlimited number of one-to-many and many-to-many relationships, preventing errors when entering data and eliminating uncertainty about product data. You can also massively replace a single part at different locations within a bill of material or in multiple dissimilar parts lists, saving you hours of time and eliminating differences in the bill of materials.

In addition, with Arena PLM you can record information about material costs and analyze it on indented parts lists. With product information stored in Arena PLM, it is possible to keep track of estimates and quotations at the component level of your suppliers. This way you can calculate the costs of a brand based on quotations, previous purchases or estimated costs. Because you have access to real-time cost information for all your multi-level BOMs in Arena PLM, you can realize the impact of product costs on profitability. In addition, parts of the bill of material can be securely shared with partners, such as contract manufacturers, so that they always see the latest version and the changes.